Rochester researchers use 3D printing to create a novel, environmentally friendly material made of algae that has applications not only for energy and medicine, but also for fashion and space exploration.

Living materials, which are made by housing biological cells within a nonliving matrix, have gained popularity in recent years as scientists recognize that often the most robust materials are those that mimic nature.

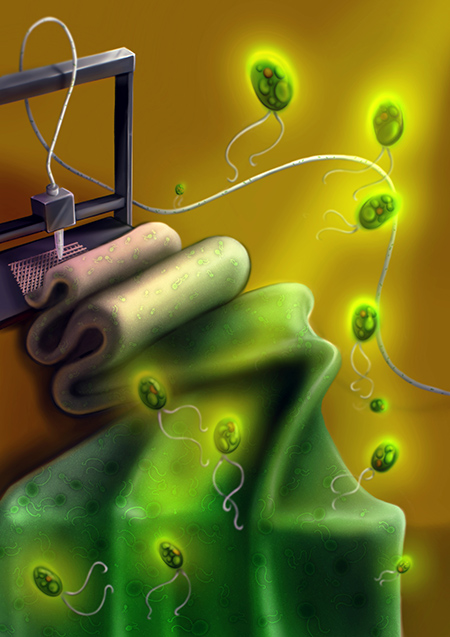

For the first time, researchers at the University of Rochester and Delft University of Technology in the Netherlands used 3D printers and a novel bioprinting technique to print algae into living, photosynthetic materials that are tough and resilient. The material has a variety of applications in the energy, medical, and fashion sectors. The research is published in the journal Advanced Functional Materials.

“Three-dimensional printing has shown to be an effective technology for fabricating living materials that have many environmental and other benefits,” says Anne S. Meyer, an associate professor of biology at Rochester. “Our photosynthetic living materials are a huge step forward for the field since they are the first example of an engineered photosynthetic material that is physically robust enough to be deployed for real-world applications.”

The work to develop a biologically based material is the latest in a series of research efforts led by Meyer’s lab. Meyer and her research team have been leaders in using bacteria to develop such industrially important materials as artificial nacre and graphene.

How to build new materials: Living and nonliving components

To create the photosynthetic materials, the researchers began with a nonliving bacterial cellulose—an organic compound that is produced and excreted by bacteria. Bacterial cellulose has many important mechanical properties, including flexibility, toughness, strength, and ability to retain its shape, even when twisted, crushed, or otherwise physically distorted.

The bacterial cellulose is like the paper in a printer, while living microalgae acts as the ink. Meyer and her colleagues used a 3D printer to deposit living algae onto the bacterial cellulose.

The combination of living (microalgae) and nonliving (bacterial cellulose) components resulted in a unique material that has the photosynthetic quality of the algae and the robustness of the bacterial cellulose; the material is tough and resilient while also eco-friendly, biodegradable, and simple and scalable to produce. The plant-like nature of the material means it can use photosynthesis to “feed” itself over periods of many weeks, and it’s also able to be regenerated—a small sample of the material can be grown onsite to make more materials.

Artificial leaves, photosynthetic skins, and bio-garments

The characteristics of the material make it an ideal candidate for a variety of applications, including new products such as artificial leaves, photosynthetic skins, or photosynthetic bio-garments.

Artificial leaves are materials that mimic actual leaves in that they use sunlight to convert water and carbon dioxide—a major driver of climate change—into oxygen and energy, much like leaves during photosynthesis. The leaves store energy in chemical form as sugars, which can then be converted into fuels. Artificial leaves therefore offer a way to produce sustainable energy in places where plants don’t grow well, including, potentially, outer space colonies. The artificial leaves produced by Meyer and her colleagues are additionally made from eco-friendly materials, in contrast to most artificial leaf technologies currently in production, which are produced using toxic chemical methods.

“For artificial leaves, our materials are like taking the ‘best parts’ of plants—the leaves—which can create sustainable energy, without needing to use resources to produce parts of plants—the stems and the roots—that need resources but don’t produce energy,” Meyer says. “We are making a material that is only focused on the sustainable production of energy.”

Another application of the material would be photosynthetic skins, which could be used for skin grafts, Meyer says. “The oxygen generated would help to kick-start healing of the damaged area, or it might be able to carry out light-activated wound healing.”

Besides offering sustainable energy and medical treatments, the materials could also change fashion. Bio-garments made from algae would address some of the negative environmental effects of the current textile industry in that they would be high-quality fabrics that would be sustainability produced and completely biodegradable. They would also work to purify the air by removing carbon dioxide through photosynthesis and would not need to be washed as often as conventional garments, reducing water usage.

“Our living materials are exciting because they can sustain themselves over periods of weeks and can be multiplied onsite, so that they have the potential to be truly long-lasting and able to be shared all over the globe as easily as sourdough starter,” Meyer says.

And now, maybe helmets, too

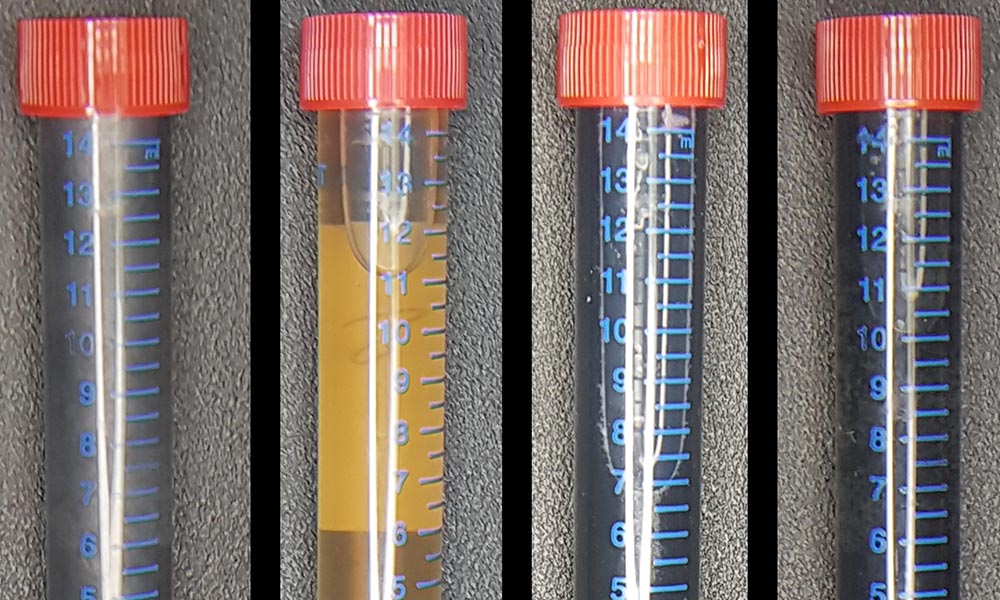

In related research published in Cell Reports Physical Science, Anne S. Meyer and her collaborators from Delft University of Technology report additional advances in using bacterial cellulose—this time in combination with calcium carbonate, a substance commonly found in eggshells and seashells—to fabricate durable materials inspired by nature. The unique characteristics of the material may make it a useful building block for everyday objects such as furniture, cellphone holders, or protective helmets.

Using bacteria, calcium carbonate, a kitchen blender, and a sieve, Meyer and her lab created material that can:

- be repeatedly dropped from a 33-foot height, or withstand a 155-pound person standing on top of it, without any apparent damage;

- withstand one minute of direct contact with an open flame without igniting or burning;

- be molded into 3D shapes, then recycled and re-molded repeatedly to form new shapes.

Read more

Will your future computer be made using bacteria?

Will your future computer be made using bacteria?

Graphene is a revolutionary nanomaterial, the discovery of which led to a Nobel Prize. By mixing graphite with bacteria, Rochester scientists are making graphene easier and more environmentally friendly to produce, paving the way for future products and applications.

Researchers create artificial mother-of-pearl using bacteria

Nacre, also known as mother-of-pearl, is an exceptionally tough natural material found in shells and pearls. Rochester biologists have developed an innovative method for creating nacre in the lab—and maybe on the moon.

Creating the model human

Physicians at the University of Rochester Medical Center have developed a new way to use 3D printing to fabricate artificial organs and human anatomy that mimics the real thing, even up to the point of bleeding when cut. These models are able to create highly realistic simulations for training and could soon be widely used to rehearse complex cases prior to surgery.