Many of the capstone projects that engineering students are completing this year could have applications not only here but abroad – for example, more efficient cooking stoves in Kenya, and a compact device to spin scaffolds of cassava starch for tissue engineering in Ghana.

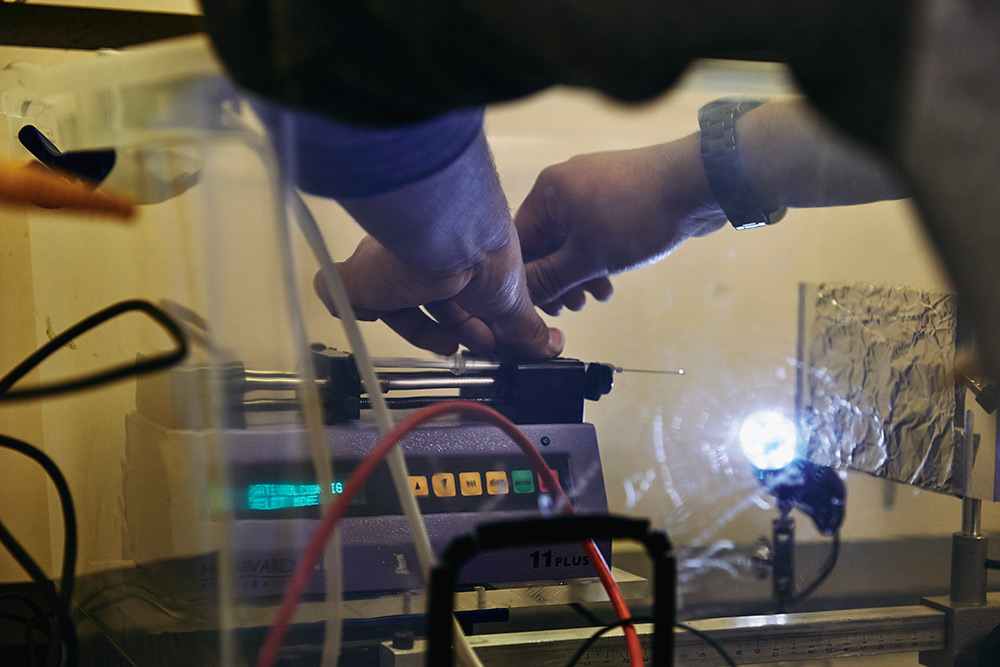

Others could have an impact right on campus – for example, the new computer and writing desks that students are designing that could be fitted together as workstations in Rettner Hall. Or a new valve one team is designing to regulate helium used in fusion reaction experiments at the University’s Laboratory for Laser Energetics.

They are among more than 70 projects that seniors in the Hajim School of Engineering and Applied Sciences will showcase with posters and prototypes on April 28 at the annual Design Day. Senior design projects give Hajim students an opportunity to truly be engineers – working in teams to translate the knowledge and skills they’ve gained through classwork and lab exercises into functional prototypes that address specific challenges.

The event will run from 11:30 a.m. to 2:30 p.m. in Goergen Athletic Center. Visit the Hajim School website for descriptions of all the Design Day projects.

More efficient cooking stoves for Sub-Saharan Africa

Biomedical engineering seniors Jessica He, YeJin Jeong, Adam Langenbucher, and Nikki Sroka have developed an adjustable “skirt” that will fit around any size pot used atop a portable cooking stove. The skirts help concentrate the rising heat, increasing fuel efficiency. Greater fuel efficiency means families spend less time or money cutting or buying fuel, which lessens deforestation. It also means less time spent standing over the stove, reducing exposure to emissions.

The students are working with alumnus Boston Nyer ’08, co-founder of BURN, a company that manufactures the cooking stoves sold to families in Kenya. Right now, the post skirts come in fixed sizes. “Research has shown there is an ideal distance between the skirt and the wall of the pot at which efficiency is highest, and that’s about 10 mm,” Sroka explained. Hence the need for a skirt that could be adjusted to that ideal distance with any of several different sized pots a family might have in it’s possession.

Concentrating solar energy

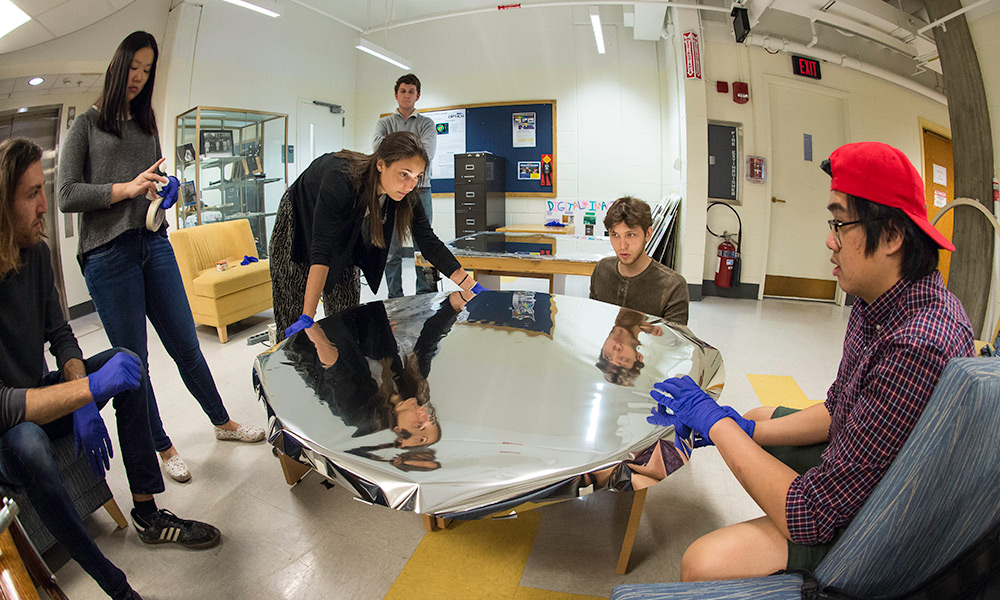

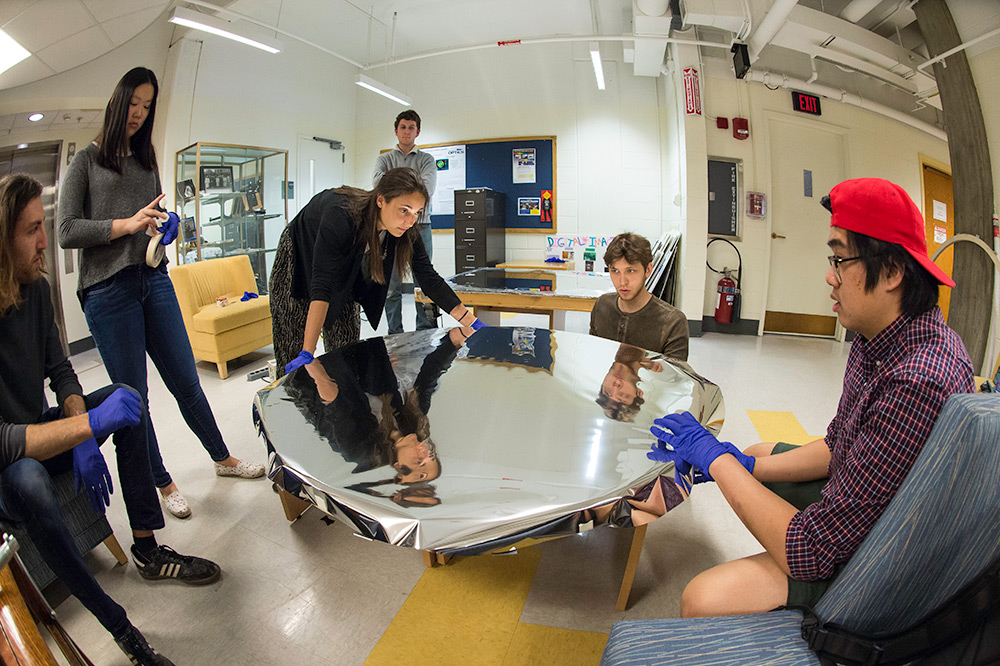

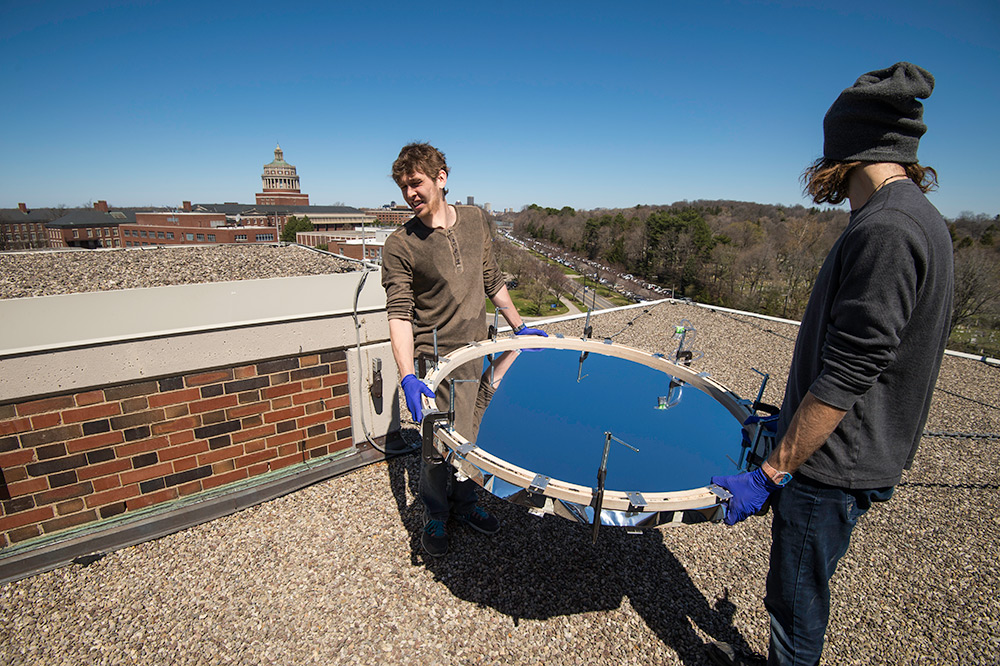

An interdepartmental team of optical and mechanical engineering students is perfecting professor Wayne Knox’s solar concentrator – a concave mirror that focuses sunlight on a small area. It could be used to sterilize drinking water and can serve as a solar oven in developing countries.

“The challenge we’re try to solve with our new frame design is how get rid of the wrinkles around the edge that plagued the original design,” said Sean Reid ’16, an optical engineering student who is also minoring in mechanical engineering. “The wrinkling warped the parabolic shape and caused the spreading of the spot size. What we’re doing with our frame is to apply a clamping force from the top and bottom around the edge of the mylar surface, rather than stretching it as much. It looks like the spot size is smaller.” Other team members are Michal Adar ’16, Jacob Blacksberg ’16, and Henry Pablo ’16 of mechanical engineering, and Michael Dupuis ’16, Bryan Maas ’16, Daniel Morgen ’16, and Fifi Song of optical engineering.

Reading braille when your fingers can’t ‘see’

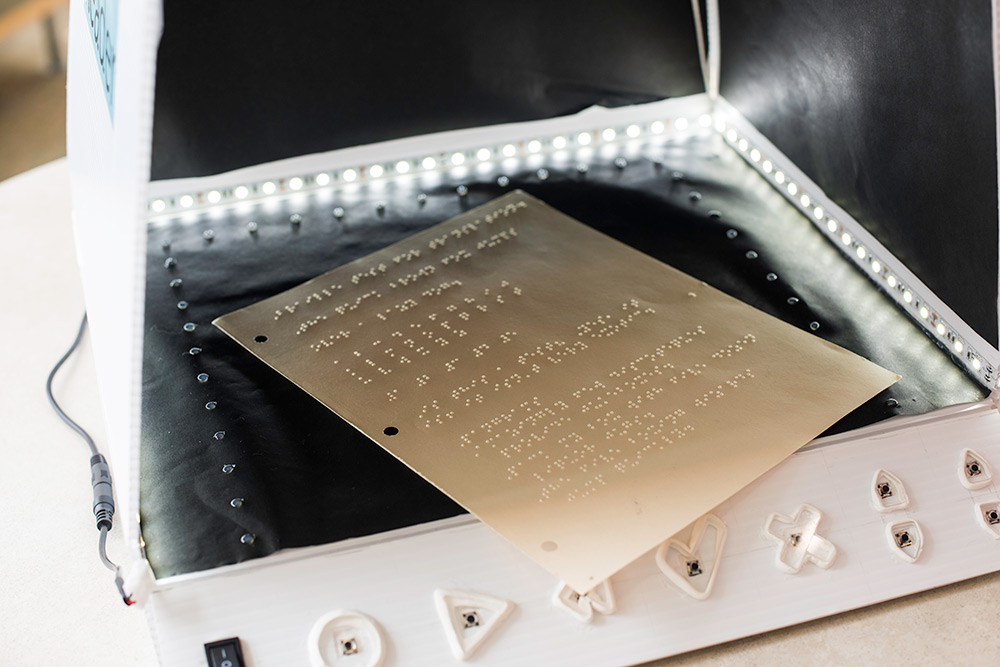

WATCH: Students demonstrate their portable braille reader, which uses a Raspberry Pi single-board computer to convert braille into spoken text.

Seventy-two percent of people with diabetes will develop diabetic neuropathy, a type of nerve damage that causes numbness in the hands and feet. For individuals who are also visually impaired, the onset of severe diabetic neuropathy means they can read neither visually nor tactilely, through the use of braille. A team of seniors — Christina Amaral, Emma Gira, Emily Kwan, Kevin McAlpine, and Matthew Mender — have worked to develop a portable device that will translate the braille documents of a person with diabetic neuropathy into audio.

The device can also be used by sighted people who need to read braille documents, for example, teachers who need to read the work of their visually impaired students.

Converting cassava roots to submicron fibers

Each Wednesday this semester, mechanical engineering seniors Christopher Dawson, Victor Montano, Cleopatra Saira, and Allesha Seenauth would go on Skype to give a progress report to Elsie Kaufmann, head of the department of biomedical engineering at the University of Ghana.

Kaufmann, who is interested in tissue engineering, has asked the team to come up with a way to convert the starch of cassava root, which is commonly found in Kenya, into submicron fibers that could serve as scaffolds – or temporary supports – for cell attachment and tissue growth.

For Seenauth, this was her first opportunity to pursue her interest in nanoscale research. The use of cassava also intrigued her; her parents are from Guyana, where cassava is also an important part of the culture. “I was really interested in how [Kaufmann] is going to implement this.”

“This is taking a technology and packaging it to create an opportunity that wasn’t there before,” added Chris Muir, associate professor of mechanical engineering, who teaches the senior design course. “That’s the great thing about engineering – that ability to take a technology and bring it into a situation where it otherwise wouldn’t be available.”

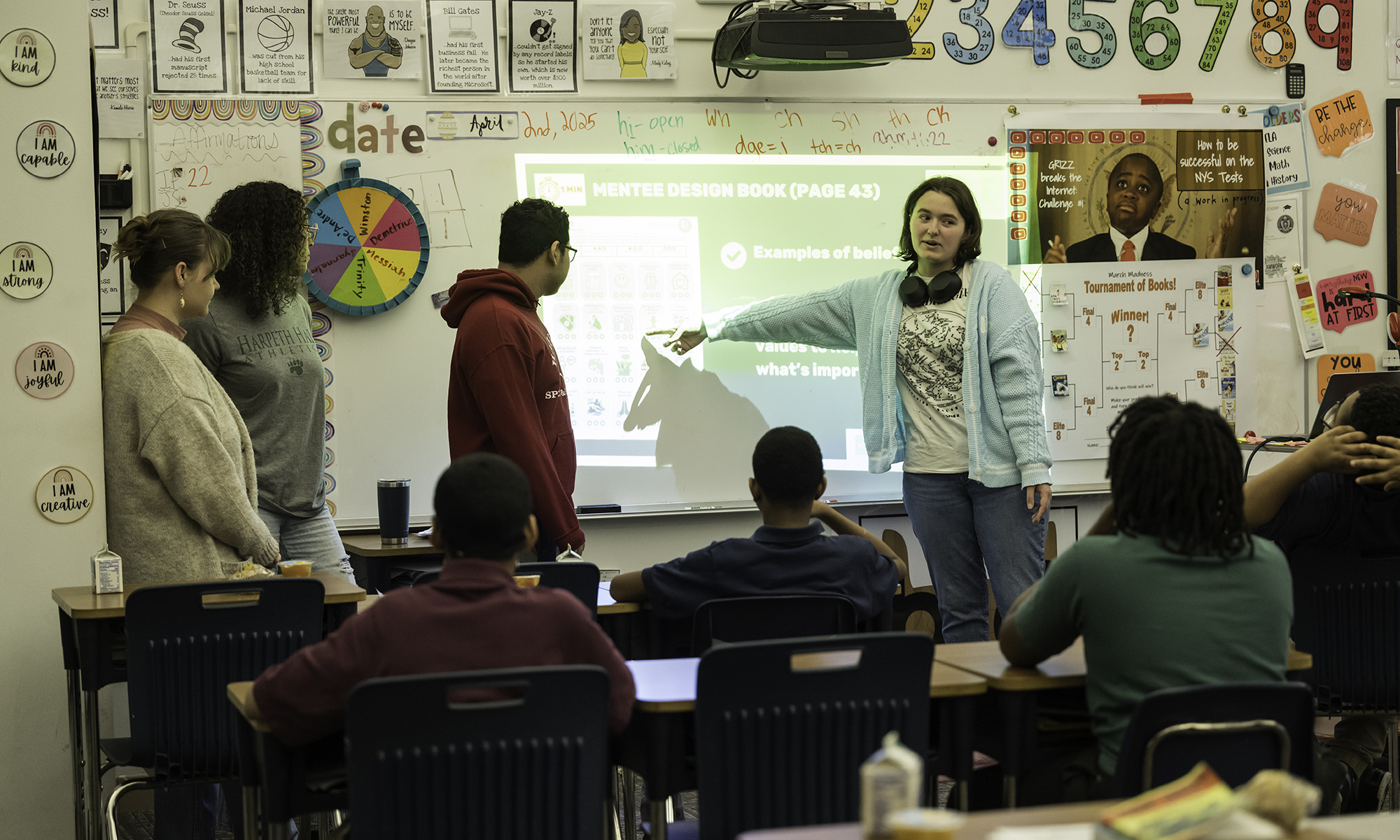

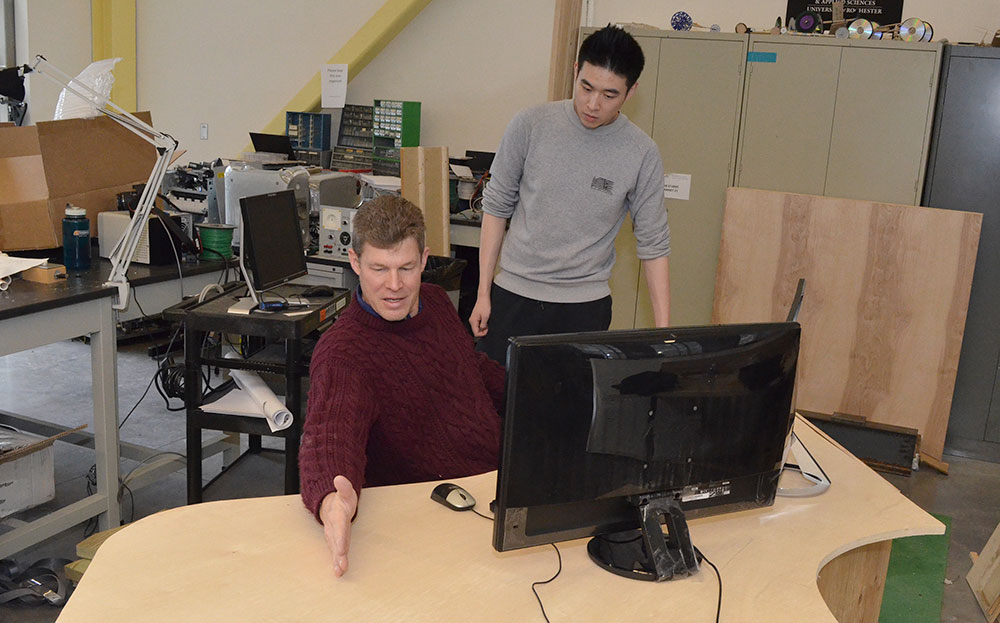

Building a better desk

A team of mechanical engineering students is designing student-friendly writing desks and computer workstations for study areas in Rettner Hall. In consultation with Mike Jarvis, professor of history and director of digital media studies the team of Harris Ackerman ’16, Hye Jin Kim ’16, Yuan Liao ’16, and Jake Meyerson ’17 settled on an L-shaped desk with rounded edges that would “immerse” the students, and could also be joined together in various configurations to encourage collaboration. “As a student-designed product, they take into account ‘consumer’ needs,” Jarvis said. “They also break with the rigid grid layout that is so unfortunately the default in many institutional settings.”