URochester researchers develop algorithms that reveal how propane becomes propylene for everyday products.

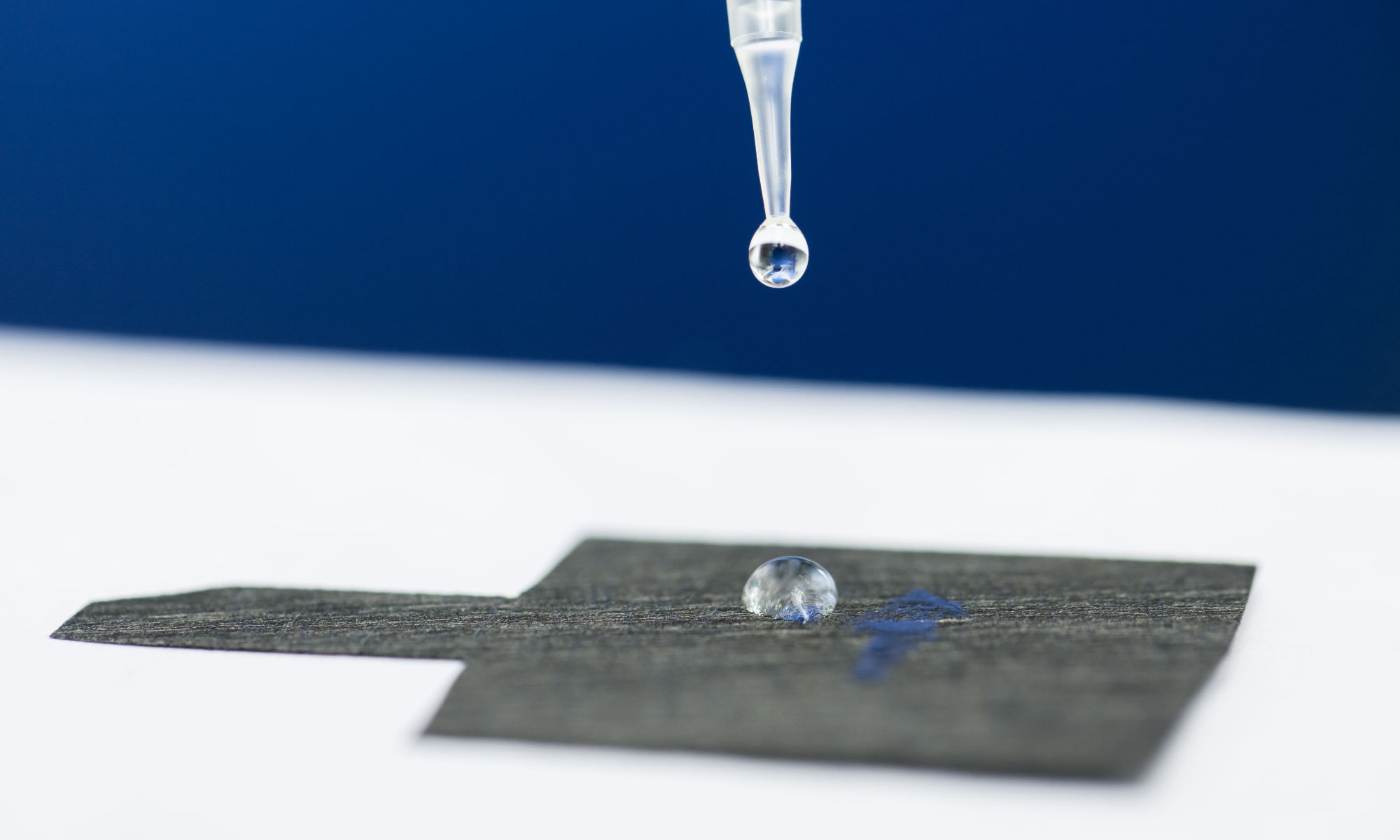

Countless everyday products from plastic squeeze bottles to outdoor furniture are derived by first turning propane into propylene. A 2021 study in Science demonstrated chemists could use tandem nanoscale catalysts to integrate multiple steps of the process into a single reaction—a way for companies to increase yield and save money. But it was unclear what was happening at the atomic level, making it difficult to apply the technique to other key industrial processes.

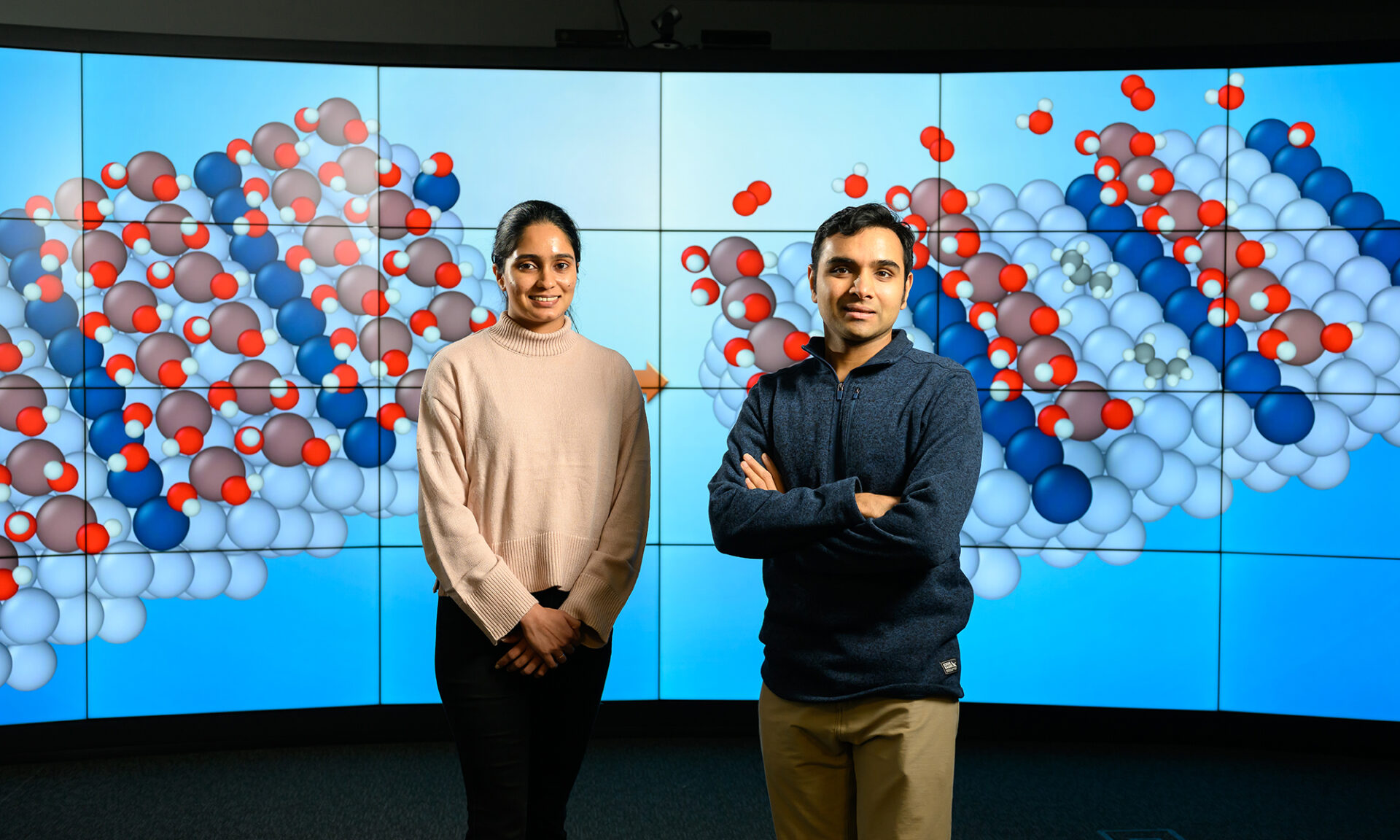

Researchers at the University of Rochester developed algorithms that show the key atomic features driving the complex chemistry when the nanoscale catalysts turn propane into propylene. In a study published in the Journal of the American Chemical Society, they discuss these intricate reactions that are complicated by materials in multiple states.

“There are so many different possibilities of what’s happening at the catalytic active sites, so we need an algorithmic approach to very easily yet logically screen through the large amount of possibilities that exist and focus on the most important ones,” says Siddharth Deshpande, an assistant professor in the Department of Chemical and Sustainability Engineering. “We refined our algorithms and used them to do a very detailed analysis of the metallic phase and oxide phase driving this very complex reaction.”

Desphande and his chemical engineering PhD student Snehitha Srirangam found several surprises in their analysis. The oxide in the chemical reaction preferred growing around defective metal sites very selectively, which proved critical for the stability of the catalyst. And even though the oxide can exist under different chemical compositions, it never really left its function of being around the defective metal sites.

According to Deshpande, researchers can leverage this knowledge and the team’s algorithmic approaches to understand the atomic structure of other chemical reactions such as methanol synthesis used for products ranging from paints to fuel cells. Eventually, he believes this could help companies strategically seek more efficient ways to produce propylene and other industrial materials and rely less on the trial-and-error methods they have used for decades.

“Our approach is very general and can open the doors to understand many of these processes that have remained an enigma for decades,” says Deshpande. “We know these processes work, and we produce tons of these chemicals, but we have much to learn about why exactly they’re working.”