Features

In this commencement season, graduates will hear a lot about following their passions. For some of those graduates, the question will be, which one? For others the question will be, will I be able to make a living? For

the graduates of liberal arts colleges, one of the less trodden paths is artisanship. As traditionally defined, artisans (or craftspeople) make objects by hand that are both useful and beautiful. More recently, that definition has expanded to include culinary artists crafting food and beverages that combine use value and visual aesthetics with the aesthetics of taste.

Rochester’s alumni include craftspeople working with a wide variety of materials. Some have made their craft their living. Others have pursued it as a second vocation. In all cases, they’ve wrestled with how to market and sell their work as changing technology has offered both challenges and opportunities.

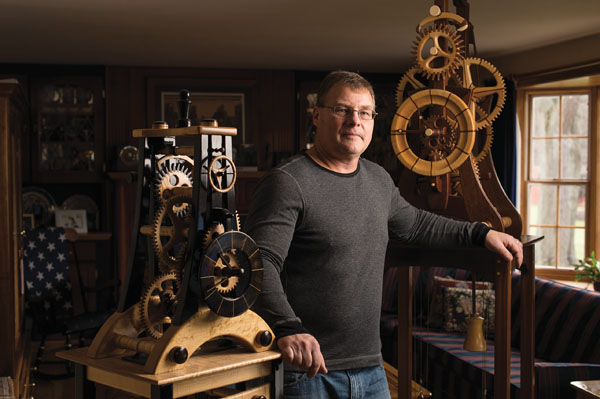

GEARED UP: Maxwell, a former art teacher and a retired Naval officer fascinated by mechanics and old navigation tools, taught

himself how to make clocks entirely from wood. (Photo: Adam Fenster)

GEARED UP: Maxwell, a former art teacher and a retired Naval officer fascinated by mechanics and old navigation tools, taught

himself how to make clocks entirely from wood. (Photo: Adam Fenster)Clock Work

Years ago, Charles Maxwell ’06S (MBA) studied fine art and elementary education at a small college in his native New Jersey. Years after that, as executive officer of Rochester’s Naval ROTC, he picked up an MBA at the Simon Business School. In the interim, he earned a master’s degree in quantitative analysis from the University of Wisconsin. He’s earned his share of degrees. But he’s an autodidact at heart, as well as a polymath.

At an early age, he began keeping sketchbooks. He filled them with drawings of things he wanted to build—go-carts, tree forts, a 6-volt battery electric motor he built from scratch in the fifth grade. “My grandfather said, ‘You’re an inventor,’” Maxwell says, sitting in his Pittsford, N.Y., home, full of cabinetry and furniture he designed and built himself.

Now retired from the Navy, Maxwell focuses on building wooden clocks, most of which stand more than five feet tall. His work makes good on a promise he made to his wife, Pat, on a museum visit during their honeymoon in Hyannisport, Mass., more than 30 years ago.

“I saw this big, wooden clock with all wooden gears, and I thought that was the most beautiful piece of kinetic art I’d ever seen,” he recalls. “I looked at Pat, and I said, ‘You know, one day I’ll build you one of them.’”

He didn’t know how a clock worked. But with a lifelong fascination with mechanics, he was undeterred. He searched libraries, museums, and the Internet, and with the sources he compiled, taught himself. He worked out specifications and sketched out designs with pencil and paper. He built mock-ups from spare material.

“The hardest part was to get the escapement to work,” he says, referring to the oscillating weight and rotating gears that allow a clock to keep time. “I went to an MIT website to help me with that.”

Complicating matters considerably was his chosen material, wood, which expands, contracts, cracks, and wears. But he’s developed methods to meet the challenges posed even by his favored ebony and hard maple, which are among the most durable woods.

He’s also designed his super-sized clocks to be easy to move. “These clocks come apart in about five minutes,” he says, unscrewing an ebony cap near the base of one of his clocks. The idea came about as a solution to a problem. “Every time you build one, you end up taking it apart a million times to get the fittings right.”

Maxwell says he hasn’t had to market himself to secure the small number of clients it takes to sustain his time-consuming craft. And as a retired military officer, he doesn’t have to make a living at his art either.

He can focus with singular attention on his goal.

“My goal is to have one of my clocks in the American Arts and Crafts Museum in New York City,” he says. (The museum changed its name to the Museum of Arts and Design in 2002.) “I have a friend who’s a naval officer who has a canoe in there.”

Maxwell has received advice, of course, on how to achieve the ambitious goal. But the key lies in the craft of clock making itself. And it’s fairly simple, in concept at least, if not in practice. “You have to have the best one out there,” he says.

REFLECTIONS ON GLASS: Glasner’s first encounter with a glass studio was like love at first sight. “It’s the connection to the material,” he says, that’s the essence of his work. (Photo: Adam Fenster)

REFLECTIONS ON GLASS: Glasner’s first encounter with a glass studio was like love at first sight. “It’s the connection to the material,” he says, that’s the essence of his work. (Photo: Adam Fenster)When Glass Was King

If you ask Bill Glasner ’69 what’s most satisfying about being a craftsman—or what, for that matter, makes one—he’ll tell you “it’s the connection with the material.” So it’s not surprising that he abandoned his first stab at craftsmanship—making dulcimers—when he found himself spending more time fiddling with machines than working with wood.

It was the early 1970s. He’d joined the Rochester Folk Art Guild, an artisanal and farming community located just east of Canandaigua Lake. Glasner, who is a board member of the guild, says, “One day I walked out of the woodshop, and it was about nine o’clock at night, and the door to the glass shop was open, and the furnace was glowing. And my name is Glasner. It was fate.”

At the time, glassmaking was on the rise. Although people have made glass since ancient times, for most of its history, glassmaking has been the work of guild members working in factories.

“Up until the 1960s, there was essentially no such thing as a glass studio,” Glasner says from his studio outside Victor, N.Y., in a barn that he converted himself. Glass blowing “wasn’t anything that an individual would do.”

But when the technology was developed in the 1950s by Toledo ceramicist Harvey Littleton, the individual glass artisan came into being.

From the late 1970s until just a few years ago, glass blowing was Glasner’s full-time job. His work has appeared on three continents, at museums such as the Smithsonian, the Victoria and Albert Museum in London, and the Musée des Arts Décoratif in Paris. His work is also part of the permanent collection at the Corning Museum of Glass.

Like many of his baby boom peers, he’s scaled back as he nears retirement age. While at the peak of his career, he operated a furnace around the clock, producing vases and other art objects with the help of assistants he was training in the craft, these days he makes glass jewelry. Requiring little overhead, it’s a business decision that makes sense in the changing glass art market.

“There was a period of time, from the early 1970s until around 2005, when handmade American craft was getting a lot of press and a lot of people were getting educated about what it meant,” he says. “And glass was the king of the scene.”

“I never had to actually convince people that I’m this great artist and this is great glass, and you should buy it because it expresses this fantastic idea—whatever people do.”

He says he could market his jewelry more aggressively if he had to. But with most of a successful career behind him, he finds that sales were never an end in themselves.

“Had I not been able to make a living at this, I probably would have ended up as a history teacher,” he says. As a glass artist, his contribution is in what he calls “intangible aspects to people’s lives.”

“I’ve tried to make beautiful things that will add value to people’s lives, that people enjoy having and seeing and using,” he says. “I hope, if we’re still around in 1,000 years and someone sees one of my pieces, they’ll say, ‘Hey, that’s really nice.’ That’s all. That’s fine.”

Ever-Changing Horizons

HAT MAKER: From her home in Fairbanks, Alaska, Krawiec creates hats from fleece, cotton, and an array of batik fabrics. Each

hat features a depiction of the Alaska Range. (Photo: Sam Harrel/AP Images for Rochester Review)

HAT MAKER: From her home in Fairbanks, Alaska, Krawiec creates hats from fleece, cotton, and an array of batik fabrics. Each

hat features a depiction of the Alaska Range. (Photo: Sam Harrel/AP Images for Rochester Review)To find her inspiration, Heather Krawiec ’92, ’93 (T5) simply looks out from her bedroom window.

The view is magical: the Alaskan Range, about 150 miles south of her home in Fairbanks. In the winter, when the sun makes only a brief appearance in late morning, the mountains form a dark silhouette against the low-rising sun, which casts a pink and orange glow, before dipping down in early afternoon. As spring comes, the sun remains long enough for that fluorescent glow to turn yellow, then dissipate, revealing a bright blue sky.

“It’s so hard to capture in a photograph,” she says.

She captures the view instead in fabrics.

As a child, she played with fabrics, mixing and matching, mimicking her mother, a quilter. Today, Krawiec makes fabric hats as the sole proprietor of the business she’s called Mountain Heather Creations, playing on her name and one of her favorite Alaskan wildflowers.

She makes the hats out of fleece or cotton. Wrapped around each hat is a band—a patchwork of printed and batik fabrics representing an imaginative recreation of the ever-changing Fairbanks skyline.

Krawiec moved to Alaska shortly after graduating from Rochester, where she completed a degree in geological sciences and a Take Five Scholars program based in studio art. She entered graduate school for marine biology at the University of Alaska at Fairbanks. She wanted to find a way to combine science and art, and sought to carve a niche for herself designing museum displays. “There was an Alaskan sea life center that was being built,” she says. She made a proposal to the museum, but it was unsuccessful. “I knew I didn’t really want a fish and game job, which is where I was headed, so I just quit.”

Hat making, which had been a hobby, became her full-time job. It was possible to pull off in Alaska.

Fairbanks is home to a robust craft market, and Krawiec attracted buyers almost immediately when she began selling her hats at local craft bazaars. It didn’t amount to a lot of money, but it didn’t have to.

“My life had been super simple, and that’s why making hats was a viable source of income to keep me going. Life was just a one-room cabin with a couple of dogs,” she says, describing a pared down way of life that’s fairly common in Alaska.

Now married, she spends much of her time helping her husband run his business, Dreamworks Cabinetry. But she continues to make hats, taking orders through her Mountain Heather Creations website and Facebook page, and filling a standing order from the museum store at the University of Alaska’s Museum of the North. She makes about 200 hats per year for the museum.

“I have these 50 or so fabrics in my studio and I just lay them out and put them together,” she says. “Just putting all those colors together is the joy for me.”

INDIE ARTIST: Preske, who makes jewelry from computer circuit boards, revels in art objects made from unconventional materials.

(Photo: Adam Fenster)

INDIE ARTIST: Preske, who makes jewelry from computer circuit boards, revels in art objects made from unconventional materials.

(Photo: Adam Fenster)A New Kind of Computer Art

Amanda Preske ’12 (MS) started making jewelry before she was 10, and went into business by the time she was 15. But it wasn’t until she embarked on a whimsical experiment with resin and computer circuit boards that she found her niche in the crowded handmade jewelry market.

Today, the PhD student in materials chemistry is noted for turning scraps of computer innards into bright and enticing jewelry. Her work is distinct, unmistakably hers, and garnering attention at arts festivals as well as through online venues such as Etsy.com.

Preske discovered the untapped potential of circuit boards when she was learning to use resin. “Anything that was floating around got cast in resin,” she says. Among the items floating around her family’s home in Syracuse, N.Y., were computer components scattered by her brother, who was dismantling a home computer.

“I thought, ‘Oh, a circuit board. That could be cool.’” She cast some circuit board parts in resin, turned them into jewelry, and displayed them at craft shows. “They received a lot more attention than I thought they would,” she says. “So I continued to develop them into the much better product that I have now.”

One facet of developing a finer product was developing a keen eye for a striking board.

“I find that there’s a lot of really interesting things right under the processor,” she says. “If I remove that carefully, I have some really neat things to work with under there.”

With the array of chisels, saws, and rotary blades in her Cobbs Hill apartment, she slices out the most visually appealing portions of her sizeable collection of discarded circuit boards. Then she grinds them to the shape she wants.

“Boards are mostly fiberglass and metal, so it’s messy,” she says, noting her need for protective equipment and methods to contain dust. To ensure the safety of the material for wearers, she chooses boards certain or unlikely to contain heavy metals. “But that’s also why I coat everything in resin,” she adds.

Preske attended college at the Rochester Institute of Technology. At the school, which is noted for both the sciences and the School for American Crafts, she supplemented her chemistry courses with courses in drawing, collage, and metalwork. It was an entrée into the local crafts scene, in which Preske has become a leader.

A regular exhibitor at some of Rochester’s major shows—the City of Rochester’s Lilac Festival and the Memorial Art Gallery’s Clothesline Festival, for example—she’s also spearheaded a new juried show: the Mayday Underground, which she founded with fellow artist Casey Wright in 2010. Held twice a year at Rochester’s Village Gate, it’s for what she calls “indie” artists and craftspeople—people who use materials in unconventional ways.

“Nationwide,” she says, “there are all kinds of weird, different, new approaches to art and craft. We wanted to bring that kind of aesthetic and appeal to Rochester.”

FINELY TUNED: The wood, the varnish, the shape, the placement of the bridge right down to a hair’s width—all have a discernible impact on the sound of the instrument, says Chrapkiewicz, who both makes and repairs violins and violas. (Photo: Nick Wass/Ap Images for Rochester Review)

FINELY TUNED: The wood, the varnish, the shape, the placement of the bridge right down to a hair’s width—all have a discernible impact on the sound of the instrument, says Chrapkiewicz, who both makes and repairs violins and violas. (Photo: Nick Wass/Ap Images for Rochester Review)Crafting Sound

“Violins are very sensitive and finicky things,” says David Chrapkiewicz ’70, ’72W (MA), explaining the complexity of making one.

The type of wood, its width, the shape and placement of parts such as the bass bar, in the violin’s interior, and the bridge, a thin wooden slab on which the strings rest—all have a striking impact on the character of each instrument’s sound. Chrapkiewicz’s violins are tailor made for his clients, and he makes, at most, four per year.

“Usually the fancier the soloist, the fussier they are,” he says. They’ll notice the effect of, for example, moving the bridge a human hair’s width. “It’s only like seven-hundredths of a millimeter. But it can brighten or make the violin sound harsh.”

Chrapkiewicz is not a violinist himself, but rather, a craftsman with a very keen ear. His grandfather made violins, and inspired by that example, Chrapkiewicz made his first string instrument—a balalaika—in 1969, while still a student at Rochester.

Intending to go to medical school, he loaded up on math, chemistry, and physics. It gave him a base of knowledge that he says “I apply to what I’m doing all the time.”

Chrapkiewicz is regularly invited to violinists’ and violin makers’ conferences to lecture on acoustics. He’s also engineered his own varnish, and unlike many makers, seals the interior of the instrument. The sealed interior “doesn’t make the violin immune to changes in humidity, but it makes it more resistant, so the changes don’t happen quite so fast.”

After graduation, Chrapkiewicz abandoned plans for medical school. He attended the Warner School of Education and taught middle school science just outside Rochester. But in 1975, he decided to devote himself fully to violin making. He moved to Montreal to study with two masters, Alois Vogl and Raymond Forget. In 1979, he set up his own shop.

Today that shop is the basement of his home in Washington Grove, Md., near Washington, D.C. It’s a fairly messy place, with wood scraps, shavings, and “tools thrown all over the place,” Chrapkiewicz says. He’s won multiple awards for his work, including a silver medal for tone at the 2002 Violin Society of America’s international competition. Most violins are made from maple and spruce. Spruce, used for the face, “is lightweight and relatively strong, and it transmits vibrations very well,” he says. Maple, used for the back and ribs, combines durability and beauty. “Maple is a very beautiful wood, especially when it has curl,” he says, referring to the fibers visible in some cuts of maple.

But Chrapkiewicz has also made violins from osage orange, and before its exportation was banned, Hawaiian Koa. “Violinists are very traditional. Most people, if they heard you’d used Hawaiian Koa, they’d say, ‘Nice knowing you,’ ” he says. “But even Stradivarius himself experimented with pear woods, willow, and cherry. He used other woods besides maple and spruce.”